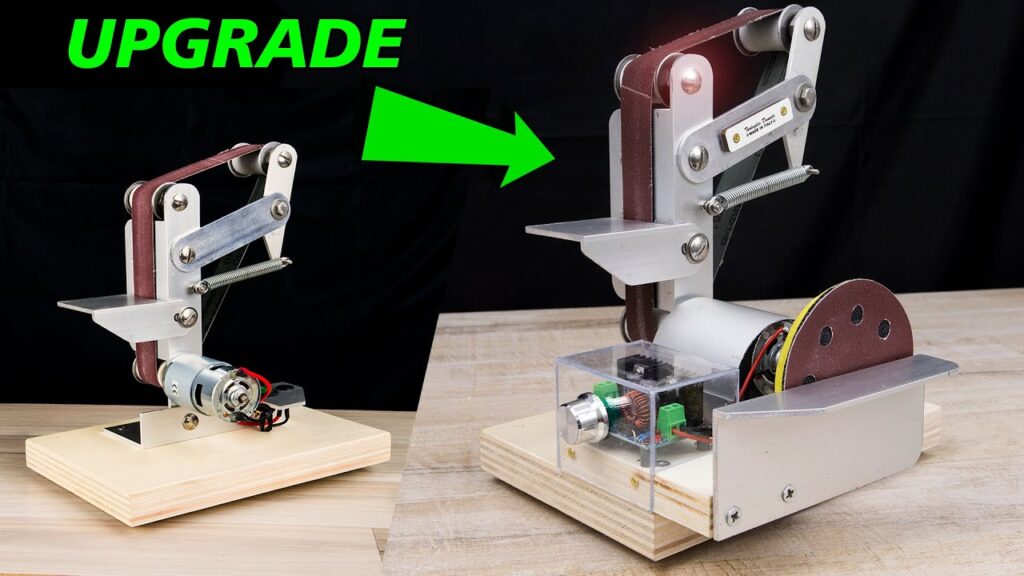

In the video tutorial titled “DIY Electric Belt Sander,” Daniele Tartaglia demonstrates step-by-step instructions on how to create a homemade electric belt sander. The tutorial provides detailed guidance on assembling the machine, showcasing its versatility as a 2-in-1 tool. Viewers will gain insight into the necessary materials, equipment, and techniques required to construct their own belt sander.

Throughout the video, Tartaglia shares product links and information related to video making equipment, tin soldering equipment, and power tools. Additionally, he provides discount coupons for special products through his TELEGRAM channel. For those who prefer commercial versions, Tartaglia suggests several alternative options. From Mini Belt Sander Commercial Version A to Drillpro Angle Grinder Belt Sander Attachment, viewers can explore a range of choices to suit their needs. Whether you opt for a DIY project or a ready-made purchase, this video tutorial presents an informative and practical guide to creating or selecting an electric belt sander.

DIY Electric Belt Sander: Video Tutorial

Click Here To Read About Seiko Watches and Rolex Watches!

Introduction

In this comprehensive DIY electric belt sander tutorial, we will guide you through the process of building your very own belt sander. With the right materials and tools, you can create a powerful and versatile tool that will aid you in various woodworking projects. We will cover each step of the process, from gathering the necessary materials to wiring the switch. By the end of this tutorial, you will have a fully functional belt sander that you can proudly add to your workshop.

Materials and Tools Needed

List of Materials

To build your own electric belt sander, you will need the following materials:

- Electric motor

- Belt sander frame materials (such as plywood or metal)

- Belt sander belt

- Switch

- Wiring

- Screws and bolts

- Adhesive or mounting brackets

- Safety goggles and gloves

List of Tools

To successfully complete this project, you will require the following tools:

- Drill

- Screwdriver

- Wrench or pliers

- Saw or jigsaw

- Sandpaper or file

- Measuring tape or ruler

- Wire strippers

- Safety gear (goggles, gloves, etc.)

Ensure that you have all the necessary materials and tools before starting this project to minimize any interruptions during the construction process.

Step 1: Gathering the Materials

Identifying the Required Components

Before you can begin building your electric belt sander, it is important to have a clear understanding of the required components. The main components include the electric motor, the belt sander frame materials, the belt sander belt, the switch, and the wiring. By familiarizing yourself with each component, you can gather them efficiently and ensure that you have everything needed for the project.

Sourcing the Components

Once you have identified the required components, it is time to source them. You can find most of these components at hardware stores or online retailers specializing in DIY projects and tools. Ensure that you choose a high-quality electric motor that is powerful enough for your needs. Similarly, select a durable and appropriate belt sander belt that suits the size and material you plan to work with. Take your time to source each component and compare prices to ensure that you get the best value for your money.

Step 2: Preparing the Motor

Disassembling the Motor

Before you can integrate the motor into your belt sander, you will need to disassemble it. Begin by carefully removing the motor casing, being mindful of any attached wires. Once the casing is removed, you can access the internal components of the motor, such as the rotor and the stator.

Cleaning and Inspecting the Motor

With the motor disassembled, take the opportunity to clean and inspect each component. Remove any dust or debris using a cloth or compressed air. Examine the condition of the motor’s bearings, gears, and brushes, checking for signs of wear or damage. If necessary, replace any damaged or worn-out parts to ensure the motor functions optimally.

Making Modifications if Necessary

At this stage, you may need to make some modifications to the motor, depending on the design of your belt sander. This could involve adjusting the size or shape of certain motor components to fit within the frame. Use a saw or a jigsaw to carefully modify the necessary parts, ensuring precision and taking safety precautions. Once the modifications are complete, thoroughly clean any debris generated by the cutting process.

Click Here To See More Luxury Watches.

Step 3: Building the Belt Sander Frame

Designing the Frame

The belt sander frame provides stability and support to the motor and the belt. Designing an efficient and sturdy frame is crucial for the overall functionality of the belt sander. Begin by determining the dimensions of your desired belt sander, considering factors such as portability and compatibility with your workspace. Sketch out the frame design, ensuring that it is proportionate to the size of the motor and the belt.

Cutting and Shaping the Frame Materials

Using the appropriate tools, such as a saw or a jigsaw, cut the frame materials according to your design. This may involve cutting multiple pieces of plywood or shaping metal pieces to fit together seamlessly. Take accurate measurements and ensure precision when cutting to guarantee a snug fit for all frame components.

Assembling the Frame

After cutting the frame materials, begin assembling the frame. This may involve drilling holes, using screws or bolts, and potentially using adhesive or mounting brackets to secure the frame pieces together. Follow your frame design and refer to the measurements and sketches to ensure accuracy during the assembly process. Take your time to align the frame elements correctly to achieve a sturdy and functional belt sander frame.

Step 4: Attaching the Motor to the Frame

Determining the Motor Placement

Before attaching the motor to the frame, determine the optimal placement that will provide the desired functionality and ease of use. Consider factors such as the belt’s path, accessibility for maintenance purposes, and alignment with the frame. Take measurements and mark the exact location where the motor will be attached.

Mounting the Motor

Using screws or bolts, securely mount the motor to the frame at the designated location. Ensure that the motor is positioned securely and tightly aligned with the frame. Double-check the stability and adjust as necessary to prevent any potential wobbling or misalignment during operation.

Step 5: Installing the Belt

Choosing the Right Belt

Selecting the appropriate belt for your belt sander is crucial for achieving optimal performance. Consider the type of material you will be working with, whether it is wood, metal, or other materials. Research different belt options and determine the grit and size suitable for your specific needs. Ensure that the belt fits securely within the sander frame and the motor pulley.

Adjusting the Tension

Before installing the belt, adjust the tension to prevent slippage or damage. Some belt sanders come with adjustable tension systems, while others require manual adjustments. Consult the instructions provided with your belt sander or refer to the manufacturer’s recommendations to ensure the correct tension setting.

Securing the Belt

Once the tension is adjusted, install the belt by carefully positioning it on the motor pulley and the rollers. Ensure that the belt is aligned properly and sits securely within the frame. Double-check the tension and make any necessary adjustments to ensure smooth operation.

Step 6: Wiring the Switch

Selecting the Appropriate Switch

Choose a switch that is compatible with the motor and suitable for the intended use of your belt sander. Consider factors such as voltage, current, and the switch’s design. Consult the motor’s specifications and wiring requirements to ensure the switch is capable of handling the electrical load.

Connecting the Wires

Begin by preparing the wires for connection. Strip the insulation from the ends of the wires using wire strippers, exposing the bare metal. Connect the wires from the switch to the appropriate terminals on the motor, following the wiring diagram provided by the manufacturer. Ensure that the connections are secure and tightly fastened.

Securing the Switch

After making the necessary connections, mount the switch to the frame in a location that is easily accessible during operation. This will allow you to turn the belt sander on and off conveniently. Use screws or adhesive, depending on the switch design, to firmly secure the switch to the frame. Double-check the connections and the switch’s functionality before moving on to the next step.

Step 7: Testing the Belt Sander

Before putting your belt sander to use, it is important to conduct testing to ensure proper functionality and safety. Securely fasten the belt sander to a workbench or other stable surface. Slowly turn on the motor and observe the belt’s movement and alignment. Check for any unusual noises or vibrations, which could indicate misalignment or other potential issues. Additionally, verify that the switch functions correctly, turning the motor on and off as intended. Take all necessary safety precautions, such as wearing goggles and gloves, during the testing phase.

Step 8: Optional Enhancements

Once you have successfully built your DIY electric belt sander, you may wish to consider optional enhancements to further improve its functionality. These enhancements could include adding a dust collection system, incorporating adjustable angle features, or integrating additional safety measures. Research different belt sander modifications and consult woodworking forums or resources to gain inspiration for these enhancements.

Conclusion

In conclusion, building your own electric belt sander can be a rewarding and practical project for woodworking enthusiasts. By following the step-by-step tutorial outlined above, you can create a reliable and efficient belt sander that meets your specific needs. Remember to always prioritize safety during the construction process and adhere to any recommended safety guidelines provided by the manufacturer. With your newly constructed belt sander, you will have a valuable tool that will assist you in a wide range of woodworking projects. Enjoy the process of building and utilizing your DIY electric belt sander!

Is The Rolex Submariner Better – Click Here to Learn More!